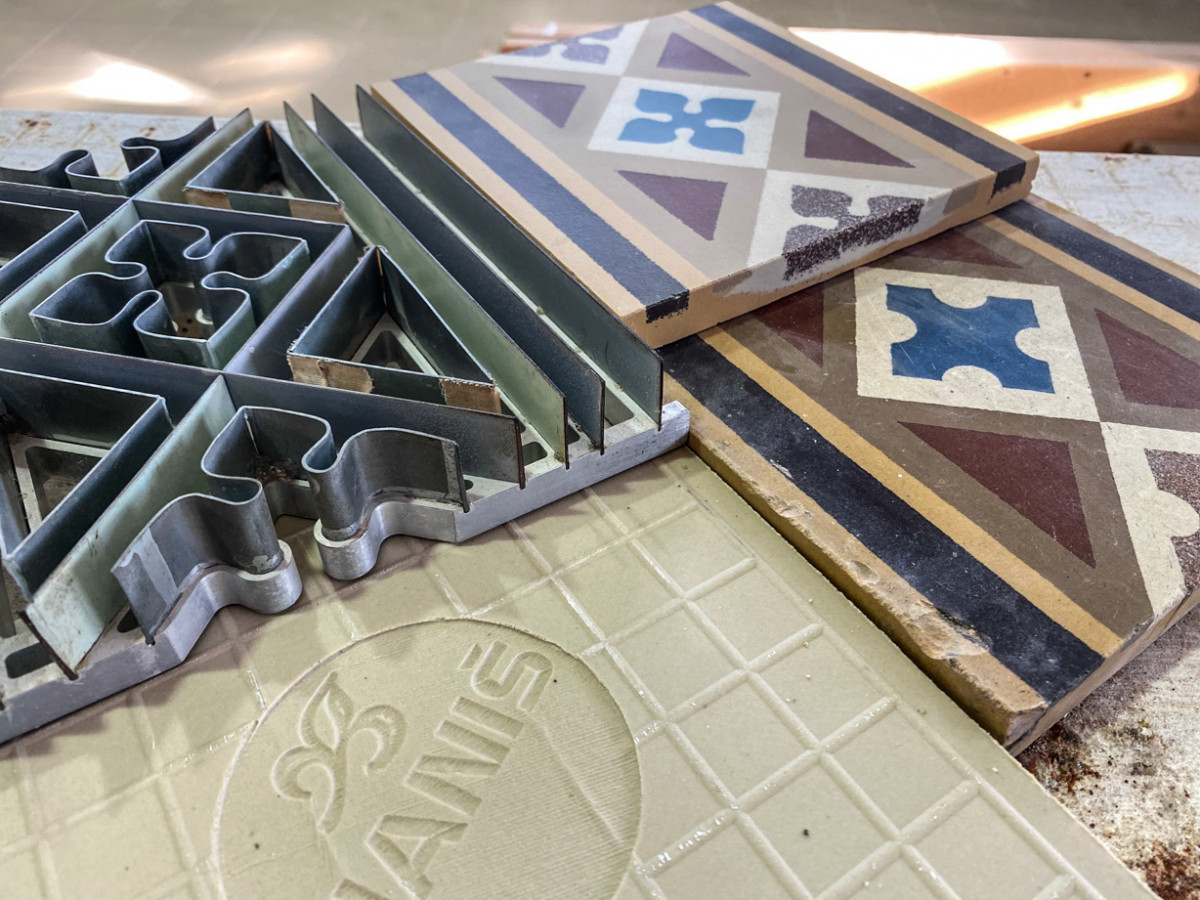

Our complex production process begins with the selection of shapes, patterns and colours for individual types of historical tiles. We can make exact copies of original patterns to create very precise replicas of hard-fired ceramic tiles that were made in the past. This is a key requirement of national heritage protection authorities when carrying out renovations and repairs in historically valuable buildings – and it is often requested by the owners of apartment blocks dating from the late 19th and early 20th centuries. But it is also the preferred option for many other demanding customers who appreciate the unique quality of hand-crafted ceramic tiles made using only traditional natural materials.

The most cost-intensive part of the production process involves creating precise press moulds, mould punches, tools and jigs. Each tile is made individually. The tile mould is hand-filled with a base material consisting of natural minerals – a mixture of kaolin, feldspar, dolomite and calcium silicate. These mineral ingredients are crushed, wet milled in water, dried, purified to remove iron, and extra pigment is then added if necessary. Because we use only 100% natural raw materials, we can only offer 15 basic colour shades (just like 150 years ago) supplied exclusively by Lasselsberger Plzeň (RAKO).

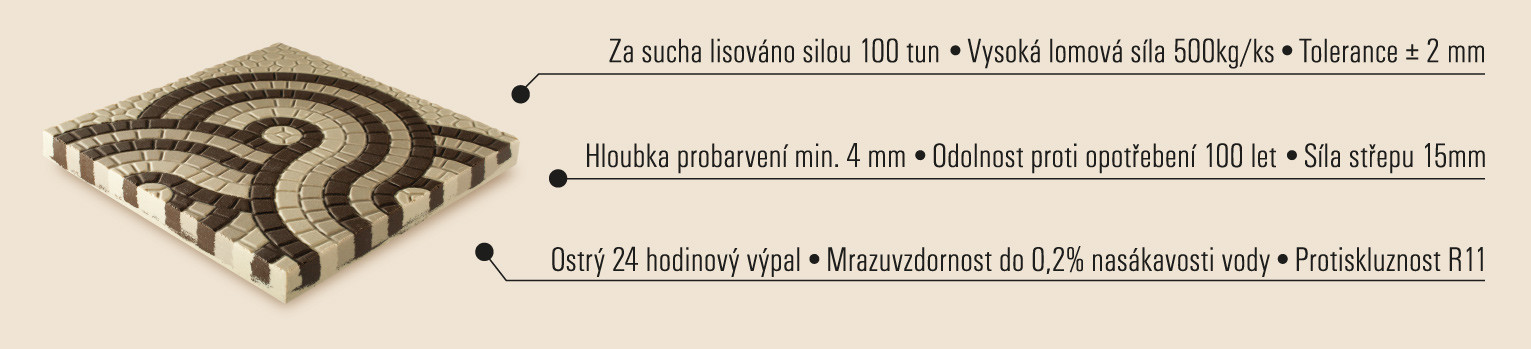

The material is poured into the individual parts of our pattern moulds, ensuring that all our tiles are pigmented to at least a depth of 4 mm. This means that the patterns are completely indestructible – even when subjected to extremely frequent traffic and heavy-duty use. In fact, the patterns in our tiles will survive completely unchanged for between 100 and 140 years!

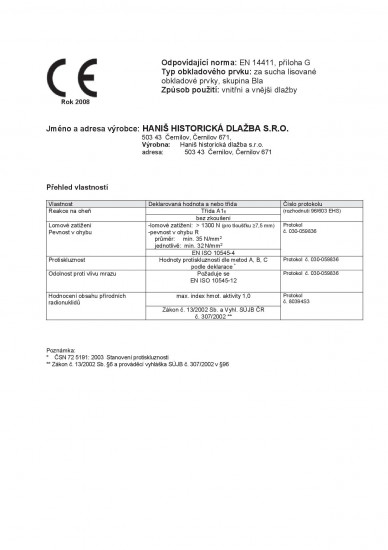

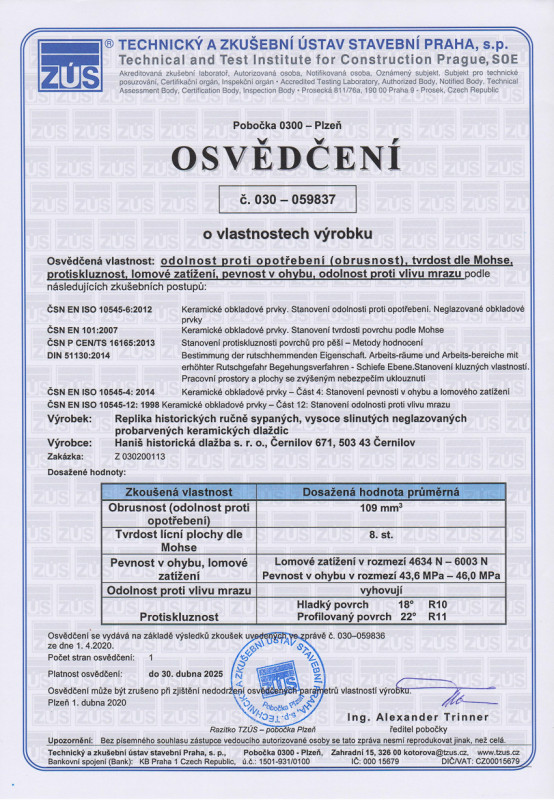

The entire production process is based on the expertise and experience of our master tilemaker, who knows the secrets of the exact proportions of ingredients to use, how to create the perfect tools for the job, as well as the precise and unique temperature curve that is necessary to hard-fire our highly vitrified ceramic tiles. All the individual phases in this process combine to produce tiles of outstanding quality – fracture strength 500 kg per tile, water absorption up to 0.2%, high utility value, excellent mechanical abrasion resistance… and above all, elegant beauty that will never fade.

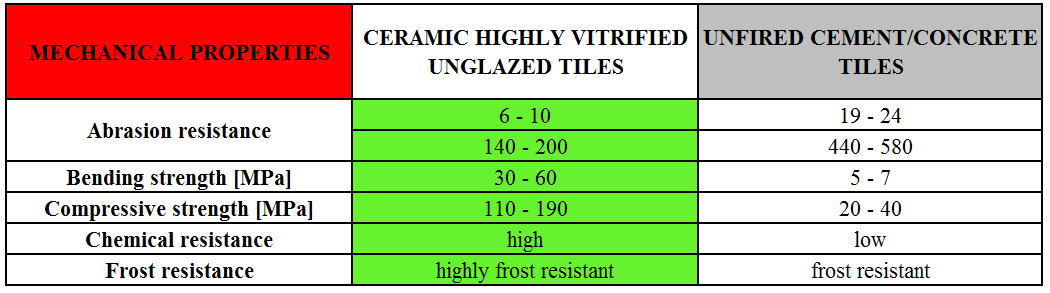

COMPARISON OF MECHANICAL PROPERTIES WITH CEMENT/CONCRETE TILES

|

|

|